Sterile Drugs can be divided into terminal sterile products and aseptic processing products. Aseptic Processing Products require that the entire process be aseptic and include sterile lyophilized powders.

1. Terminal Sterile Products

For terminal sterile products, such as large volume parenteral (LVP), the preparation and filling processes can be completed in a non-aseptic environment while the sterilization process will be completed after filling.

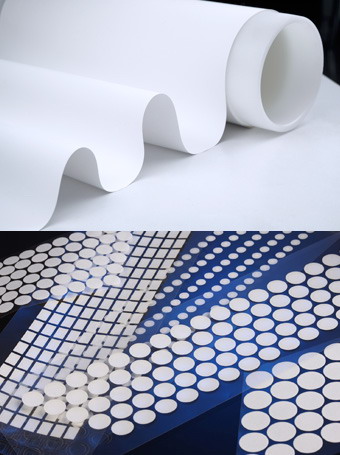

Since terminal sterile infusion solutions are directly injected into the blood system, measures must be taken to avoid endotoxin, microorganism, and particle contamination by using a 022μm-0.45μm filter during the preparation process.

2. Aseptic Processing Products

Aseptic processing products are usually heat unstable and the finished product cannot be sterilized. Sterilized and non-sterilized production areas must be kept separate. In addition, all non-sterile material must be sterilized prior to flowing into the sterile area. Production staff must be prepared per Standard Operating Procedures (SOPs). As an example, for lyophilized powder, a 2 or 3 stage filtration process should be used after preparing the solution but before filling. It should be filtered with a 0.22μm filter.